Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

What Are The Main Differences Between GB 50367-2013 And ACI 440.2R-17?

GB 50367-2013, "Code for Design of Reinforced Concrete Structures" (China), and ACI 440.2R-17 (USA) are generally similar in their design concepts, calculation methods, and construction requirements for carbon fiber (CFRP) reinforced concrete structures. However, there are some key differences. The following is a comparison of the two:

1. Design method and safety factor

| Item | GB | ACI |

| Design Method | Based on Limit State Design, Partial Factor Method (similar to Eurocode) | Based on Strength Reduction Factor Method (LRFD, US specification system) |

| Material Partial Factor | CFRP Material Property Partial Factor (γ_f = 1.1-1.4) | Environmental Reduction Factor (C_E = 0.65-0.95) |

| Concrete Strength Requirements | Reinforced concrete strength ≥ 15 MPa (C15) | Reinforced concrete strength ≥ 21 MPa (3000 psi) |

2. Material properties and parameters

| Item | GB | ACI |

| CFRP Ultimate Strain | Flexural Reinforcement: ≤0.01 (Test verification required) | Flexural Reinforcement: ≤0.006 (to control debonding failure) |

| Shear Reinforcement Intrinsic Strain | U-Wrap: ≤0.002; Full Wrap: ≤0.004 | Effective Strain ≤0.004 (considering reduction factor) |

| Bond Strength Calculation | Using an interfacial bond formula based on concrete strength | Empirical model based on FRP stiffness and concrete strength |

3.Structural Requirements

| Item | GB | ACI |

| End Anchorage | U-hoops or mechanical anchors are clearly required, with anchor lengths ≥ 200mm. | End anchorage is recommended, but no minimum length is specified. |

| Time Between Multiple Layers | ≤ 30 minutes between each layer (epoxy resin). | Depends on the resin curing time (usually ≤ 1 hour). |

| Fire Protection | Fireproofing coating is required (e.g., cement mortar ≥ 25mm). | Protection measures are recommended, but the specific thickness is determined by fire protection regulations. |

4. Loads and combinations

| Item | GB | ACI |

| Load Combinations | According to GB 50009 | According to ASCE 7 |

| Dynamic Load Reduction | CFRP Strength Reduction Factor 0.5 under Fatigue Load | Fatigue Reduction Factor 0.55 (Based on Testing) |

5. Construction and Acceptance

| Item | GB | ACI |

| Hollowing Detection Standards | Single hollow area ≤ 100 cm², total area ≤ 5% | Hollowing area ≤ 1% and maximum diameter ≤ 50 mm |

| On-site Testing Requirements | A positive tensile bond strength test (≥ 2.5 MPa) is required. | Not mandatory, but sampling testing is recommended. |

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

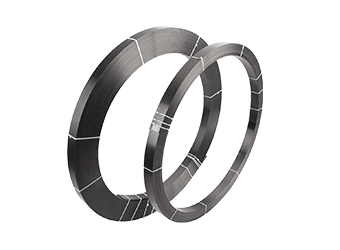

HM-1.4TT is a high strength, high modulus unidirectional carbon fiber reinforce polymer(CFRP) laminate for structural strengthening

HM-1.4TM is a high modulus unidirectional carbon fiber reinforce polymer(CFRP) laminate for structural strengthening

Unidirectional carbon fiber plate/strip/laminate for concrete repair and structural strengthening